Our history, beginning in 1972

From a repair shop to a high-tech injection-moulding company.

A family-run business focused on innovative plastics technology.

Our factory, equipped with state-of-the-art production machines.

Through the constant modernisation of our machine park, materials handling and product removal facilities, we are able to meet the growing requirements of our customers at all times.

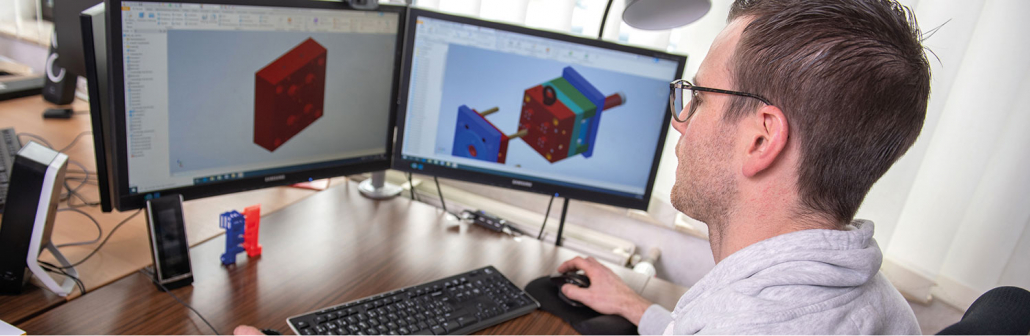

Our service – know-how through experience

Short communication channels – A one-stop-shop from the design of a component, via the making of the moulds to the production of the injection-moulded products.

Our quality assurance system and the environment

Our quality assurance system monitors and comprehensively documents all production steps, from the arrival of the raw materials to the delivery of the finished products. State-of-the-art processing technologies help us to keep rejects to a minimum. We use nothing but “green electricity” and are doing everything possible to reduce our packaging footprint through multiple use or reusable containers.

We have greatly reduced our energy consumption through speed-controlled drives for our injection-moulding machines, servo motors instead of pneumatics in our robots, as well as modern water re-cooling systems (with the waste heat used to heat our buildings).

Our team

Ernst, Helmut und Alexander Jost (left to right) are your direct contacts. They are there to provide answers to any questions you might have.

A family-run business, the 3rd generation is now involved in managing the company.

Contact – how to reach us

The company moved to the “Morsheck” industrial estate in Büllingen in 1992, where our premises have since grown to over 2500 m².