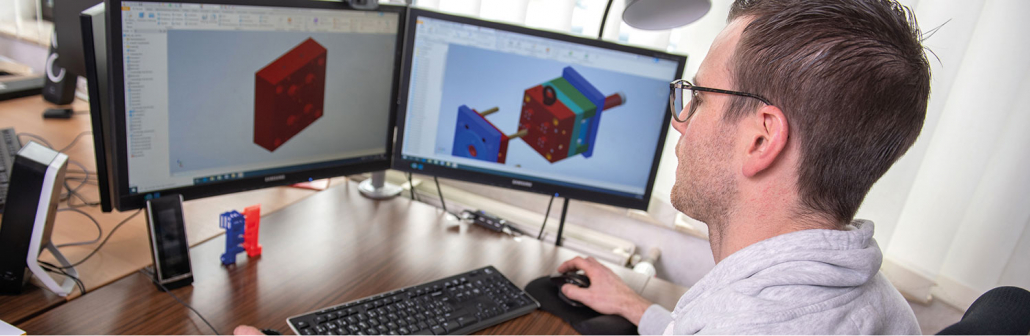

Tool construction

In-house repair and maintenance shop. Our in-house mould-making facility (CAD in the construction department and CAM for making the moulds) allows us to supply high-quality products with short lead times. Immediately a customer gives the go-ahead, series production starts.

Plastic technology

We work with all regular thermoplastics with a part weight of 0.5 to 1500g, using state-of-the-art injection-moulding machines with a locking force of 500 to 3200 kN (as of April 2020). Well-known companies, above all in the construction industry, cable-makers, household appliance producers and the filter technology specialists, have been working with us for years in a spirit of trust.

Development

From the drawing board to series production: the short communication channels here at our Morsheck plant ensure efficient product development, from the drawing board to series production. In each development phase, we are there to help you. Alongside common plastics such as PE, PP, PA, PC …, we also use such special plastics as PBT, TPU, POM, Copolyester (BPA-free) or PA4.6 for certain applications.

Quality and environment

Our quality management is implemented in a consistent manner in all production areas. When developing a new product or selecting raw materials, we attach great importance to an optimal design aimed at minimising the use of raw materials, reducing packaging and transport, and recyclability.

Permanent production monitoring ensures that any faults are detected at an early stage and that raw material usage is kept to a minimum. The production data collected is used for continual improvement.

Photos from our production lines

Examples of the many products manufactured here: From the simplest washer to complex filter housings with automatic thread unscrewing technology

Team

Ernst, Helmut und Alexander Jost (left to right) are your direct contacts. They are there to provide answers to any questions you might have.

A family-run business, the 3rd generation is now involved in managing the company

Contact – how to reach us

The company moved to the “Morsheck” industrial estate in Büllingen in 1992, where our premises have since grown to over 2500 m².